Echte Damaststahlmesser

Damaststahlmesser

Im „wilden Damast“ werden über 300 Lagen eines zähen und elastischen und eines harten Stahls in einem bis zu 2 Tage dauernden Prozess manuell zu einer Klinge von höchster Perfektion und optischem Genuss geschmiedet.

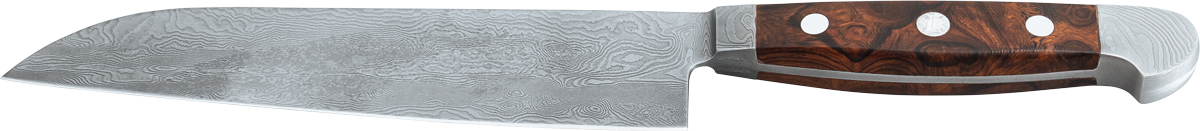

Kochmesser Damast

1.762,00 €THE KNIFE. DAMASCUS STEEL SMOKED OAK

2.969,00 €Bread knife Damascus

6.084,00 €Santoku Damast

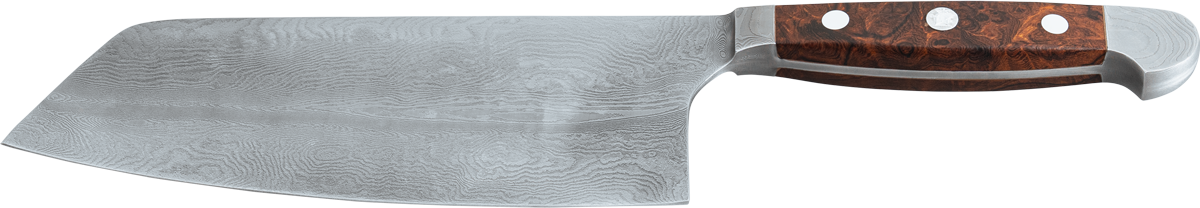

2.329,00 €Chai Dao Damast

2.402,00 €Kochmesser Chinaform Damast

2.400,00 €Spickmesser Damast

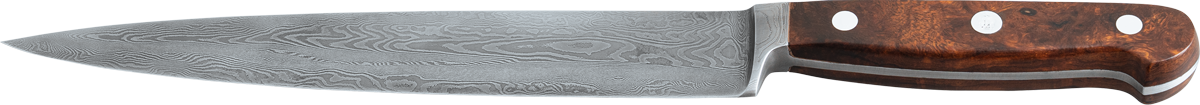

934,00 €Schinkenmesser Damast

1.533,00 €Fleischgabel Damast

1.542,00 €DAMASK STEEL KNIFE

Nach weiteren 50 manuellen Arbeitsgängen wird daraus ein von Hand geschmiedetes Damaststahl-Unikat. Die Messer sind selbstverständlich nicht spülmaschinenfest und nicht rostfrei. Als Griffmaterial der Damastmesser der Serie Alpha dient extrem hartes, bis zu 1.500 Jahre altes Wüsten-Eisenholz. Der Griff der Damast-Version von THE KNIFE. ist aus Grenadill-Holz.

Ein aus Damaststahl geschmiedetes Messer sein eigen zu nennen, ist wohl der Wunsch manch eines Messerliebhabers. Über die reine Funktionalität hinaus ist es vor allem die faszinierende Optik und die Handwerkskunst des Schmieds, die dieses Material so begehrlich machen.

Where does the name come from, where does the myth of damask steel come from?

The origin of the word "damask" can be found in the capital of Syria. Until the 18th century, a steel from the Indo-Persian region was imported to Europe via Damascus. The characteristic feature of this steel was a pattern. However, it is not known exactly how this steel was produced (source: Wikipedia).

Even today, in the age of post-industrialisation, producing a steel of homogeneous, consistent quality requires a high degree of experience and process reliability in production. And so one can imagine that the difficulties before industrialisation - in the Middle Ages and in antiquity - were incomparably greater. For apart from the quality of the steel, it was above all the skill and experience of the blacksmith that made a good knife. It goes without saying that the quality varied from smith to smith, from knife to knife.

The blade steel of knives must not only be homogeneous and of consistent quality. It must also meet sometimes contradictory requirements. It is therefore crucial to weigh up the different requirements and to ensure an optimum. On the one hand, the knife steel should be hard, but not too hard, otherwise there is a risk that the blade will break under heavy use. On the other hand, the knife steel should not be too soft either, as the knife would lose its sharpness too quickly in use due to constant wear.

It was therefore important to combine the properties. Because a steel that fulfilled all requirements at the same time could not be produced in consistent quality. And so a hard steel, which promises initial sharpness and edge retention, was combined with a tough steel, which gives the knife the necessary flexibility and resistance to breakage. It was important to position the hard steel where the bevel/edge would be on the finished knife.

For everyday use, the hardness of the steel that forms the edge should not be too high. Damascus knives from GÜDE have an edge that is hard and cutting, but not too hard so that it can be easily resharpened.

At the beginning of a damask knife is a package of several layers of steels of different hardness (usually two or three). The package is heated in the forge, fire-welded and then separated lengthwise or crosswise, laid on top of each other and fire-welded again. This is done as often as necessary until the desired number of steel layers is achieved. In the process, the blacksmith has to make sure that a certain temperature is not exceeded. Otherwise the carbon in the steel would burn. What follows is craftsmanship on the part of the blacksmith with hammer and anvil.

By twisting the steel package during folding and forging, different patterns can be achieved on the surface. The knives finally receive their visual appeal in an acid bath. There, the different layers and flow lines are worked out into a decorative pattern.

Damascus knives from GÜDE - a feast for the eyes. Almost too beautiful to work with.