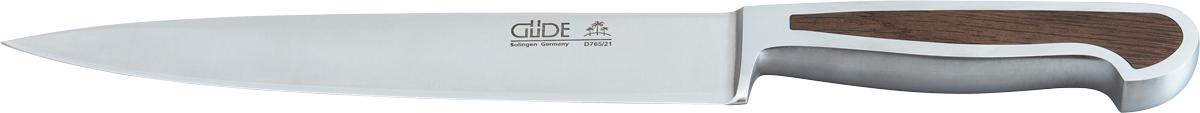

Perfect balance and elegant design

Delta

Hand-forged stainless steel blades with inlaid handle scales made of fine, dimensionally stable smoked oak, which ensures high hardness and a polishable surface.

Chef's knife Delta

163,00 € - 197,00 €Price range: € 163.00 to € 197.00Select version This product has several variants. The options can be selected on the product page

Bread knife Delta

212,00 €Delta preparation knife

131,00 €Larding knife Delta

114,00 € - 124,00 €Price range: € 114.00 to € 124.00Select version This product has several variants. The options can be selected on the product page

Delta paring knife

114,00 €Tomato knife Delta

140,00 €Fillet knife Delta

163,00 €Delta ham knife

163,00 €Porterhouse steak knife Delta

140,00 €Delta meat fork

160,00 €Delta sharpening steel

164,00 €Delta

The particularly elegant handle scales of the Delta series made of smoked oak are slightly raised. Smoked oak is characterized by its characteristic dark colouring and attractive grain and is valued for its robustness and stability for high-quality furniture and decorative elements. Due to the smoked oak inlays, the handles are not dishwasher-safe. The solid design and the generous use of materials give the knives in the Delta series an incomparable balance and make cutting a special experience.

The knives in the Delta are hand-forged from a single piece of chrome-vanadium-molybdenum knife steel and are then finished in over 40 manual operations. They are stainless, ice-hardened and offer unique weight distribution and balance thanks to the all-metal design with smoked oak inlays. The traditional method of manufacture and the innovative, high-quality design have earned the Delta series more than just one award.

Material

The blade material of knives has to meet a wide range of requirements, some of which are contradictory. It is therefore important to achieve an optimum between the different requirements. A knife steel should be hard, but not too hard, otherwise it would break. But it should also not be too soft, otherwise the knife would become blunt too quickly through wear. That is why the knives in the Delta series from GÜDE are made of a chrome-molybdenum-vanadium knife steel that has an optimum hardness of approx. 57-58 HRc (Rockwell).

The hardness of the Delta series knife steel of 57-58 HRc is ideal for the various requirements that a good knife must fulfill. Thanks to this hardness, the blade of the Delta series knives is torsion-resistant and therefore guarantees exact guidance of the knife and therefore a precise cut. But even a hard steel, such as GÜDE knife steel, can be very flexible if it is ground very thin. A flexible blade such as the Delta fillet knife is particularly suitable for filleting fish by moving the blade back and forth between the skin and fillet with a slight bend.

Production

Knives in the Delta series are drop-forged from one piece of steel. Drop forging ensures high material strength even under dynamic stresses. During drop forging, the entire forging blank is heated and deformed. In a further 40 or so steps, the forged blank is turned into a unique handmade knife from the knife manufactory GÜDE.

After the knives have been roughly ground, calibrated, and cleaned, they undergo a process known as ice hardening: the knives are cooled to -80 °C to improve the microstructure of the blade steel. In the next step, the knives are tempered in two stages, i.e., reheated to make them break-proof. The blade is then pre-ground, followed by pre-grinding of the knife back. This is followed by fine grinding of the knife back and point grinding of the bolster. The inner sides for the inlays are now pre-ground. The pre-grinding of the bolsters is carried out in 5 steps. This is followed by the fine grinding of the blade. This is also called "pliesten." Now the knife back is finely ground. The fine grinding of the front bolster follows and the knife handles are pre-polished. The smoked oak inlays are now inserted. The handles are then finely polished. The knife edge, also known as the bevel, is then ground (honed) and the bevel is polished. The special GÜDE is now applied to the bread knives, and the hollow edge to the hollow-edged knives. Tomato, cheese, and steak knives are given their serrations. In the next step, the GÜDE is etched onto the blade. The knives are then cleaned and their quality is checked. After that, the knives are placed in a protective sleeve. Finally, the shipping bags are fitted with rivets and the appropriate labels. The finished knives are then sent to the warehouse for shipping.

Form

In drop forging, the design language is free from the tip of the blade to the end of the handle. A design language like that of Delta is only possible in the drop-forging process. That is why GÜDE has remained true to this proven technology since its founding in 1910, now in its fourth generation. An unmistakable feature of many series from GÜDE is the so-called double bolster. A bolster is the thickening of the blade steel. The (front) bolster between the handle and the blade serves both as finger protection and balance weight. The second bolster at the end of the handle gives the knives a better balance. This guarantees the user pleasant and fatigue-free work.

The front and rear bolsters of the Delta series knives merge seamlessly into the handle. This is because the knives in the Delta series are forged from a single piece of steel from the tip of the blade to the end of the handle. This results in a unique weight distribution and balance. No seam, no material transition - just drop-forged from a single piece.

Function

A good knife must be sharp, stay sharp, fit well in the hand and be balanced so that fatigue-free and safe working is guaranteed at all times. The hardness of the GÜDE blade steel with approx. 57-58 HRc (Rockwell) and the GÜDE wading angle of approx. 33 degrees ensure optimum sharpness and edge retention of the Delta series. The shape of the all-metal handle with inlays of smoked oak and the typical GÜDE double bolster guarantee perfect handling and balance of the Delta series knives.

The bevel angle is particularly important in terms of sharpness and cutting performance: this is because cutting is "physically" the driving of a wedge through a material being cut. The sharper the angle of the wedge, i.e. the bevel angle, the better this works. Bevel is the term used by knife makers to describe the cutting edge, i.e. the sharpened part of a knife. A sharp bevel angle makes a knife sharper than a blunt bevel angle. However, if the bevel angle is too sharp, the bevel can break. That is why the knives in the Delta series Delta GÜDE have GÜDE optimal bevel angle of approx. 33 degrees. This angle guarantees both sharpness and stability. The chrome-molybdenum-vanadium knife steel used in the Delta series, with a hardness of approx. 57-58 HRc (Rockwell), Delta that the sharpness lasts for a long time. This requires cutting on a suitable cutting surface, e.g., made of wood or plastic. The proverbial balance of the Delta series knives Delta thanks to the double bolster in combination with the all-metal handle and the smoked oak inlays. This creates a counterweight to the blade in the handle area. For the user, this means perfect balance and fatigue-free working. A secure grip is always guaranteed. The front and rear bolsters enclose the hand and thus protect against unwanted slipping, even when greater force is applied. The knives in the Delta series Delta what ambitious amateur chefs expect from a perfect knife. Handcrafted, forged from a single piece of metal, with the experience of centuries of Solingen knife-making expertise.

Our knife series

We value individuality - especially in the development and optimisation of our knife series. This is reflected in every single blade that leaves our manufactory, in the selection of particularly beautiful and tactile handle materials and a unique ergonomic design that fluently enables and celebrates fast, precise work.

Gourmet x Güde

The exclusive "Feinschmecker" edition combines genuine craftsmanship from Solingen the high standards of Germany's leading gourmet magazine.

Discover knife icons

THE KNIFE.

Our THE KNIFE. lives up to its name: this all-rounder was conceived, developed and forged by us with a particular focus on perfect ergonomics. Its special shape and balance ensure an automatic over-grip of the hand, which encloses the blade when cutting and thus finds a quasi natural extension in THE KNIFE.

Bread knife

Developed in 1941 by the heir to the manufactory Franz Güde , the special "GÜDE serrated edge" of our bread knives today delights bakers and bread lovers all over the world. The pointed teeth of the unyielding, sharply ground chrome-vanadium-molybdenum steel ensure that breads, baguettes and rolls can be sliced instead of squashed, but also cabbages, melons and crispy crusted roasts can be cut more easily than ever. Unadorned, beautiful handles made of different high-quality materials do the rest for this knife legend of ours.

Utility knife

Our compact all-round talent is handy and effective - not only when it comes to precise work with smaller items. Its fine serration and double-sided hollow grinding make our universal knife the ideal companion for peeling, cutting and slicing vegetables, meat, fruit and co.